401, Building 5, Jiangbian Industrial Fifth Road, Jiangbian Community, Songgang Street, Bao'an District, Shenzhen +86-18123725135 [email protected]

Shenzhen RMG Optoelectronics co.Ltd.( abbreviated : RMG LED ) was founded in May 19th, 2016.

It is a comprehensive emerging optoelectronics enterprise that integrates the research and development, design, production, sales, and senvice of indoor and outdoor ful-clor LED displays, rentalLED screens, fiexilble LED screens, transparent LED screens, film screens, holographic screens, spherical LED electronic screens, specia-shaped LED displays, interactive for tile screens withgravity sensing,naked-eve 3D fu-color screens, and relted product aplcations, this also one ofthe domestic senice providers of LED product appication system solutions.

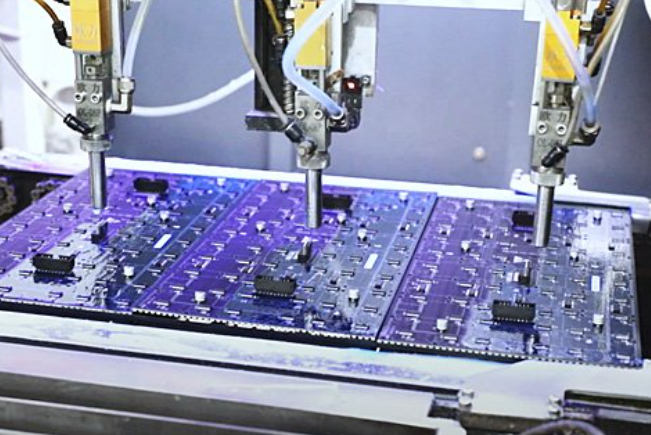

RMGLCD LED display factory is equipped with first-class automated production equipment, which is the basis for us to achieve efficient and high-quality production. In particular, the surface mount technology (SMT) equipment we introduced can efficiently and accurately mount LED components on circuit boards to ensure the reliability and consistency of each LED display.

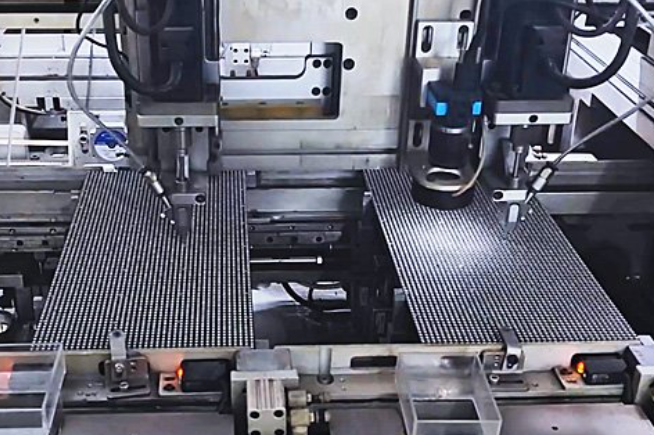

Baking is an important step to ensure the reliability of lamp beads. In order to avoid a large number of dead lights, SMD lamp beads are usually baked before use.

IC SMT needs to brush solder paste first, then paste IC, resistors, capacitors, power sockets, and signal sockets, and reinforce them in reflow soldering.

The lamp bead surface patch also needs to be brushed with solder paste first, then patched on the SMT machine, and reinforce them in reflow soldering.

After the LED patch is completed, the first lighting test is carried out.

Three anti-paint can protect the PCB circuit board from environmental erosion; after curing, it forms a transparent protective film.

Fix the bottom case to the PCB with screws.

We ensure that the assembly of each LED display meets the highest quality standards. RMGLCD has an aging line, which simulates the actual use conditions by running it for a long time, and finds and solves potential problems in advance.

After the LED module is produced, it will undergo an aging test for more than 12 hours to ensure that there are no problems before proceeding to the next step.

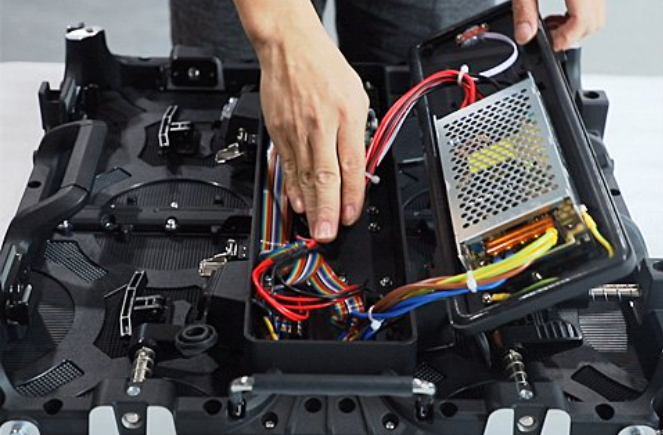

Skilled workers assemble the LED module, power supply, receiving card and cabinet together.

After the LED cabinet is assembled, the entire display is built and subjected to an aging test for at least 72 hours.

RMGLED provides factory OEM services and welcomes consultation and cooperation.

Learn More About RMGLED ?